Australia Tel: +61 (0)3 8720 6700

Indonesia Tel: +62 21 3040 4422

New Zealand Tel: +64 (0)7 850 2610

South Africa Tel: +27 (0)10 900 2055

Compaction Grout Monitors

Description

Grout Monitors

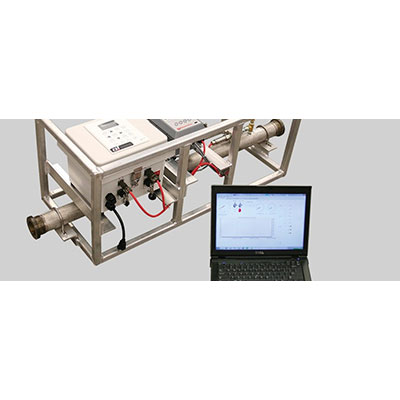

Grout monitors provide real-time display of key grouting parameters to enhance the understanding of site conditions. The data they provide are invaluable in providing a permanent record for quality assurance, quantity documentation, and pressure and flow readings. RST’s grout monitors provide information about borehole grout’s pressure, flow, injected volume, apparent Lugeon, penetrability control, and GIN. The data they collect can be transmitted to a computer base station over a wi-fi connection, providing automatic unattended monitoring if desired. Their user-friendly software allows for displaying the trending graphs of pressure and flow, as well as other graphs associated with grouting theories and practices.

RST’s grout monitors find applications in any operation that makes use of grouted boreholes. Both permeation and compaction grout monitors are available to suit the type of grouting operation. The permeation grout monitor can handle grout flows of 3 l/min to 300 l/min while the compaction grout monitor can handle flows between 0.2 and 5.0 CFM. For low mobility/high pressure applications, wired and wireless header pressure monitoring is available.

DESCRIPTION

The RST Compaction Grout Monitor System provides operators and engineers real-time display of key grouting parameters to enhance the understanding of site conditions. It is invaluable in providing a permanent record of key grouting parameters for quality assurance, quantity documentation, pressure and flow readings.

The data logger incorporates wi-fi that transmits data to a portable computer on which an operator can visualize displays of real-time and historical injection pressure and flows.

The RST Compaction Grout Monitor System has been developed and tested for a 2.0 in. flow tube. A short (< 50’) header connection of high pressure/low dilation, wire braid reinforced hose is recommended. For low mobility/high pressure applications, wired and wireless header pressure monitoring is available.

APPLICATIONS

- Provide the operator with a real-time display of key grouting parameters to enhance the understanding of site conditions.

- Provide a permanent record of key grouting parameters for quality assurance, quantity documentation, pressure and flow readings.

QUICK SPECS

SENSOR SPECIFICATIONS

- Materials: Compaction and low mobility grouts

- Flow: 0.2 – 5.0 CFM (2.09 – 37.4 GPM)

- Temperature: -20°C to 85°C (-4°F to 185°F)

- Grout Pipe Sizes 2.0 in.

- Pressure Transducer: 0 – 1000 or 0-2000 PSI (please specify) 0.25% FSO

- Connector: 2.0” heavy duty concrete placement flange

- Accuracy: ±2% above 0.3 CFM (after on-site calibration)

LOGGER SPECIFICATIONS

- Storage: 4 MB standard memory

- Data File: Comma delimited ASCII data file for post processing

- Batch Control: Keypad display to file

- Reading Rates: 2 to 10 seconds

- Real Time Graphical Display (English or SI Units): Pressure, Flow, Injected Volume and Site Specific Information