In terms of Belt Conveyor Protection in its Engineered Products portfolio, HMA Instrumentation offers:

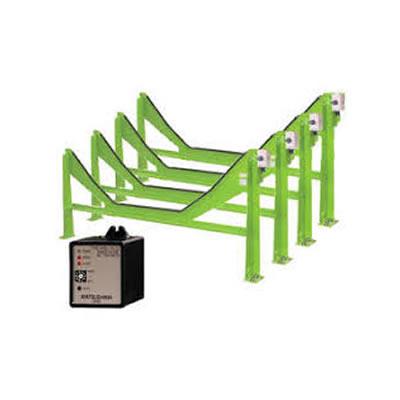

Conveyor Belt Sway Detector: The Matsushima Motor-Operated Adjusting Carrier from HMA Instrumentation requires no extra installation space. It can be mounted easily on a conveyor, and is built to operate under even severe environmental conditions. It replaces conventional manual adjustment and simplifies conveyor-belt maintenance.

Conveyor Belt Chute Switch: The Chute Switch from HMA Instrumentation is a safety switch vital to belt conveyors. When a transport material clogs a chute, the Chute Switch stops the installed belt instantly by emitting an alarm signal.

Conveyor Belt Pull Cord Switch: The Pull Cord Switch from HMA INSTRUMENTATION can stop the belt conveyor at any position, as it is installed at the side of the belt conveyor, with the pull cord mounted along the conveyor. The large-size switch allows for large cord tension and durability.

Conveyor Belt Speed Switch: The Speed Switch from HMA INSTRUMENTATION initiates the detection by means of an integrated output relay when the shaft speed of the machine is reduced below the set speed. The Speed Switch is a non-contact type motion sensor that can be used even in severe outdoor environments.

Conveyor Belt Magnetic Type Speed Relay: The Speed Relay from HMA Instrumentation is a mechanical-type motion sensor for monitoring the operational speed of belt conveyors, cranes, and crushers, etc.

Conveyor Belt Tear Detector: The Matsushima Belt Tear Detector from HMA Instrumentation can be installed without any modifications to the belt conveyor, and while the conveyor is operating. It can detect longitudinal tears of conveyor belts due to steel pieces and/or bars instantly.