Pneumatic Purge Contents Gauges: The Measurement Resources Pneumatic Purge Contents Gauge 160 Series from HMA Instrumentation utilises the well-proven bubbler (air reaction) technique to measure liquid level and/or contents. There are two standard versions for different application and site considerations.

Custom Liquid Level Gauges: DIESSE Magnetic Level Gauges from HMA Instrumentation indicate the level of fluid inside a tank by using the magnetic properties of its elements. These are manufactured exclusively according to the centre-to-centre distance specified by the customer.

Bubbler (Hydrostatic) Level Gauges: The Hawker Bubbler (Hydrostatic) Level Gauges from HMA Instrumentation are suitable for all corrosive and non-corrosive liquids. The Level Gauges feature integral continuously-rated air pumps for up to 3 m, and can be used with optional regulated air or an inert gas supply.

Self-Powered Contents Gauge (100 Series): The Measurement Resources 100 Series from HMA Instrumentation converts the hydrostatic head pressure of liquid in a vented tank in order to deliver accurate, continuous remote contents gauging. The gauge is completely self-powered, without the need for batteries, electrical, or pneumatic supply. This makes it totally safe for use in flameproof/explosion-proof and Zone 0 areas.

Bypass Level Gauge/Magnetic Level Indicators: Bypass Level Gauges from HMA Instrumentation can also be equipped with magnetic switches and level transmitters (magnetostrictive or reed type). Advantages are a simple, robust, and rugged design, no direct contact with aggressive fluids by sensitive measurement and indicating instruments, and guaranteed operation of the magnetic roller indicator without requiring an auxiliary power source, even in the event of power failures.

Overtank Level Gauges: The KSR Magnetic Level Indicators/Gauges from HMA INSTRUMENTATION feature a communicating bypass chamber flanged to the side of a vessel. As the liquid level in the tank rises or falls, a float with a built-in magnetic system inside the chamber rises or falls along with it.

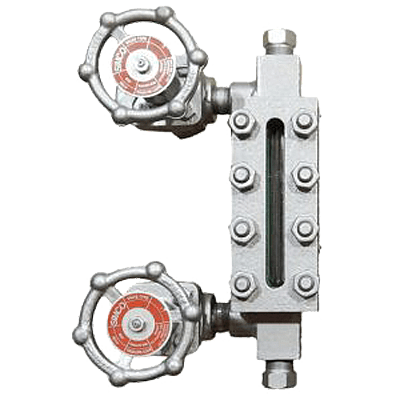

High-Pressure Level Gauges: Glass level gauges give very accurate level readings, making them the ideal product for calibrating other instruments as well. They play a crucial role during system start-up.