Solid Level Switches

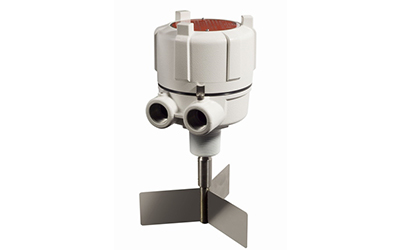

Vibrating Level Switches are a piezoelectric device with a single, blade-shaped vibrating element that provide accurate point level detection of powders and dry bulk solid materials in silos, bins and tanks. The blade of the sensor vibrates if there is no material covering the active element. When the blade is covered, the material dampens the vibration, forcing a relay to switch and indicating a covered condition. When the blade is uncovered, the vibration will restart and the relay will indicate an uncovered condition.

The vibrating rod principle overcomes difficulties typically associated with changes in temperature, humidity, material density and dielectric constant. The balanced blade design ensures a low loss tip-sensitive vibrating system, which only requires a small amount of energy and prevents the blade from digging holes and causing false alarms. The sharp edged blade also allows material to easily flow by, preventing material build up and bridging.

Capacitance Level Switches can be used to detect the presence of a wide variety of solids, liquids and slurries. The switches utilise an electrode embedded into the sensor to detect changes in the capacitance as the process fluid nears the sensor face. Once the trigger point is reached, the sensor switches to create the desired output.

Sensors can be manufactured to custom lengths for mounting on the top or side of a vessel, or can be supplied as flexible probes for free suspension. Electronics may be integral to the sensor or housed within an external controller and isolated from the process. As they are sensitive at the tip only, Capacitance Level Switches are well suited to applications which can become contaminated such as glues, bitumen and clay or in interface applications such as aerated cement powder and oil/water interface detection. They contain no moving parts, ignore coating and build-up, are simple to install, clean and maintain, and can be designed for high temperature and pressure applications.