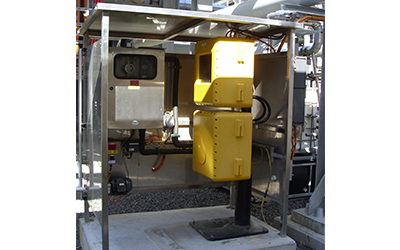

Icon Flash Point Analyser

More Information

INS-DS-0271 FlashPoint Analyser

Australia Tel: +61 (0)2 9428 7300

Indonesia Tel: +62 21 3040 4422

New Zealand Tel: +64 (0)7 850 2610

South Africa Tel: +27 (0)10 900 2055

Description

The Icon Scientific FlashPoint Analyser from HMA Instrumentation measures the lowest temperature at which typically kerosene or diesel fuel forms a flammable vapour mixture with air. The analyser heats a sample and applies a test spark to the headspace above the liquid. Delivering exceptional results, the safe storage temperatures for various petroleum products can be determined.

Using sample heating and spark ignition to measure flash point, the Icon Scientific FlashPoint Analyser from HMA Instrumentation correlates well with standard laboratory tests, and is immune to sulphur compounds. It is equipped with computer-controlled air and sample flow rates, positive spark detection, integral sample cooler, internal camera and electrode decoking system.

These state-of-the art features allows for spark observation and electrode inspection without having to open the explosion-proof box. The results are compatible with those produced by any standard flashpoint test methods such as IP170, ASTM D92 and ASTM D93.

Features include:

Inbuilt sample metering pump: Internal, programmable flow metering pump provides more accurate flow-rate control than traditional flow meters.

Mass flow controller: Provides programmable air flow and more accurate flow rate control than traditional flow meters.

Inbuilt inspection facility: An internal camera enables flashpoint observation without the need to open the explosion-proof box, rendering the entire process safer and easier to monitor.

Spark electrode cleaning system: Air is blown through the electrode assembly during cooling. The electrodes are sparked to remove any deposits that have

Formed, keeping them clean and allowing for routine maintenance without having to open the explosion-proof box.

Return to Pressure option: Where no atmospheric return point is available, an internal recovery unit returns against back pressures up to 5 barg.

In-built sample cooler: A Peltier-based sample cooler ensures that the incoming sample is cooled below the flashpoint temperature.

Atmospheric pressure compensation: The analyser results are adjusted according to atmospheric pressure as defined in the standard test methods.