QUU utilise a flow/pressure modulation system management model whereby domestic and commercial water supply reticulation system pressure is increased with a respective increase in system flow demand and conversely pressure is decreased with a decrease in flow demand. This effectively negates pipe friction effects and delivers a relatively constant system pressure independent of flow demand.

The greater Brisbane Council region has a large network of pressure reducing valves. All of these are telemetry directed and flow modulated. Put simply they turn the system’s pressure down when demand is low and turn it up when demand is high.

The sheet was cut to size and fitted as a lining on a diversion chute coming off of a conveyor carrying dry mix cement (cement powder and sand mixed with 10 to 14mm aggregate) in to a hopper. The conveyor feeds two hoppers with half the product going to each hopper.

The Memory-Flex™ disc and Disc Accelerator™ are the only moving parts; there is no packing, mechanical hinges, pivot pins or bearings to wear out or rag. Furthermore, the one-piece precision moulded disc is backed by a 25 year warranty for the flex portion of the disc to give operators confidence in the long term performance

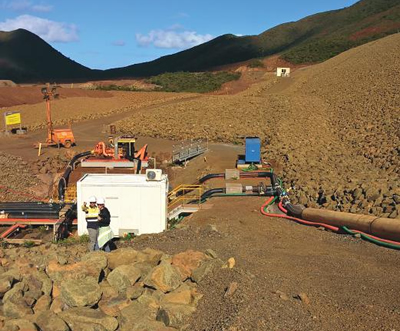

A tailings dam at an Australian mine had vibrating wire piezometers which were measuring the pore water pressure of the dam. Readings from the piezometers were being taken manually; however, the regularity of the

readings was interrupted by harsh weather, site hazards, staffing and related factors.

HMA Geotechnical has supplied its Wisenmeshnet® wireless infrastructure monitoring system for one of the largest industrial projects in Eastern Indonesia. This is the first time that this system, intended mainly for mining and civil engineering, has been adapted successfully for such an application.

The PT PLN (Persero) on behalf of Government of Indonesia is undertaking the Asahan III Hydroelectric Power Plant project in North Sumatra, Indonesia. The project involves the construction of a hydroelectric power

plant with a total power generation capacity of 174MW. The project will feature two units of 87MW capacity.

2 October 2020: The catastrophic failure of a tailings dam in Brazil in January 2019 released a mudflow that advanced through the mine-owners’ offices, staff amenities, houses, farms and roads downstream, with multiple fatalities in its wake.

Vale New Caledonia (Nouvelle Calédonie) operate a large nickel and cobalt mine, with pre-installed Geotechnical Instrumentation. HMA Geotechnical in conjunction with Campbell Scientific Australia (CSA) were contracted to supply a datalogging system that met the safety monitoring requirements of the end user, to monitor all existing vibrating wire piezometers and provide timely access to calculated data.

After a previously successful installation of ShapeArrays for HMA and a satisfied customer, Phase II of the Reclamation project for PT Petrokimia Gresik was commenced. As part of the Reclamation Phase II project, construction activities were to be conducted close to existing gas pipelines. Recognising the requirement for safety monitoring, HMA Geotechnical were engaged to

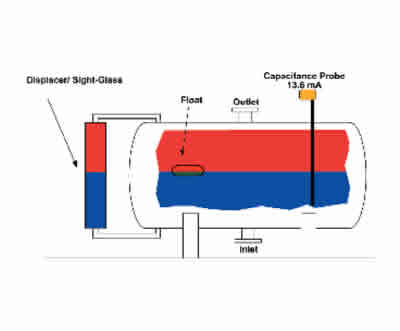

It is all too easy to forget that the primary function of the desalting system is the removal of inorganic chlorides and other water-soluble compounds from crude oil. One need not be a corrosion specialist to realize the acids that form from these compounds can do tremendous, long-term damage in downstream processes of the refinery (as the inspection of crude tower overhead condensers can prove).

Free Water Knock-Outs, Desalters and Dehydrators are just some of the applications in the oil industry where it is necessary to separate water and oil. The density differences between water and oil causes water to drop to the bottom of a separation tank, and oil to rise to the top.

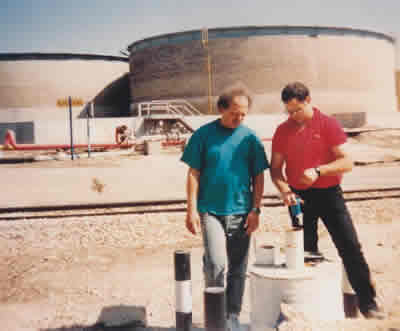

Leakwise Oil Spill and Leak Detection systems are installed in many oil/fuel storage facilities all over the world. The systems are being used in a variety of applications to address health and safety directives, environmental regulations and economic necessity.

The unique capabilities of the Leakwise Oil on Water Monitoring Systems enable remote measurement of oil presence for: Site assessments, Recovery wells and remediation systems, Well closures. The data can be transmitted to remote data loggers or computers via local wired processor or via satellites, cellular, or point-to-point wireless communications.

Hydrocarbon leakage, from Underground Storage Tanks (USTs) and from the bottoms of aboveground tanks, can seep into the groundwater, where it forms a floating oil sheen, growing to a thick oil layer over time. This layer, if left undetected, will eventually dissolve and cause severe damage to water quality.

Storm water accumulated on a concave floating roof of an oil storage tank may affect its floatation, making it necessary to immediately drain the water. This is usually done through a flexible pipe, running from the floating roof down the tank, with an outlet above the ground near the bottom of the tank.

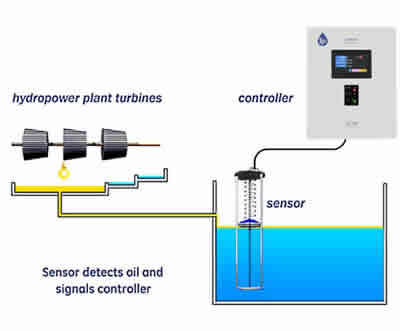

Water may carry oil leaked from turbine bearings and lubricating/cooling systems into deep sumps built under the turbines. In most plants, pumps installed at the bottom of the sump discharge the water directly to the river.

Fuel fired power generation plants have several oil storage tanks for feeding fuel to the power units. Coal or gas fired power generation plants also have oil storage tanks to be used for start-up or as a back-up energy source.

Utilities have hundreds of transformer substations. In each substation, there are usually several transformers. Each transformer contains a high volume of cooling oil.

Pipeline companies install oil collection containments in sensitive locations along the pipeline (e.g. near rivers and/or groundwater drinking wells) for oil leakage monitoring. When an ID-223 Oil Sheen Detector installed in such a containment detects oil or oil on water, it sets off an alarm in a remote location.

Oil is used extensively in all types of transportation. Oil leaks can occur during fueling and maintenance, and also during regular operation.

Often there is a need for quick field measurement of gas condensate concentration in produced water, such as when performing process optimization, water treatment verification, as well as routine process monitoring. Rigorous laboratory analysis methods such as gravimetric oil & grease measurements or gas chromatographic methods are not sufficiently sensitive to process changes and/or do not provide the required quick turnaround.

Aircraft hangar fire detection and protection systems are critical to protect the contents of the hangar and the facility itself. While a regional fixed base operator hangar might price out at $150,000 and a commercial jet airliner hangar at a few million, the commercial or military aircraft inside hangars can easily cost hundreds of millions of dollars.

Constructed in 1957 Upper Yarra dam is located 23km

Northeast of Warburton, Victoria.

In 2017 Melbourne Water announced that upgrades of the

dam wall and surrounds were necessary.

In 2019 the first stage of upgrades began with the second

stage commencing in 2020.

HMA Geotechnical became involved with the upgrades

mostly through improved logging equipment, Instrument

cable extensions and Weir monitor calibrations.

Re-routing instrument cables and preserving them during

construction was a major undertaking.

To relieve traffic pressure on the existing Harbour Bridge

and Tunnel, the NSW Government sought expressions of

interest to build a second tunnel to the Western side of the

harbour in July 2020.

In June 2021, NSW 2021-2022 budget allocated $6.3

billion over the next four years for the Western Harbor link

to go ahead.

In Dec 2021the geotechnical investigation was awarded to

GHD and SMEC.

HMA Geotechnical was selected to provide the

instruments and installation equipment for boreholes in

nine locations.

Site work commenced mid-February 2022

Construction of Keepit Dam began in the late 1930’s but

was delayed during WW2. Work was restarted after the war

and only reached completion in 1960.

The mass concrete main dam and several rock-filled

saddle dams give a storage capacity of 425000 megalitres.

Keepit Dam has undergone recent upgrades, the most

recent was to strengthen the concrete structure using post

tensioned cables.

This work would ensure potential overturning effects

during flood and/or earthquake events would be mitigated

HMA Geotechnical was contracted to supply large

diameter Vibrating Wire load cells and logging systems

to monitor the tensioning of the reinforcing cables and

thereby the load in kN.

HMA Materials Handling designs and builds a unique package for Scania. The rail truck is to be deployed by the rail infrastructure unit within the Department of Planning Transport and Infrastructure (DPTI) in South Australia.

At 287 giga litres Cardinia Reservoir is Melbourne Water’s

second largest reservoir. Constructed in the early 1970’s

it has no direct catchment, instead water is fed via Silvan

Reservoir and more recently the Victorian Desalination

Plant.

With recent improvements in dam safety and design

standards Cardinia Dam has slipped below best practice

guidelines in dam safety.

The upgrade to Cardinia dam will bring the fifty-year-old

structure back into compliance with the guidelines issued

by the Australian National Committee on Large Dams.

(ANCOLD)

Melbourne Water has a duty of care to comply under the

Water Act 1989 for all dams within its portfolio.

The upgrade works are due to start in 2024/25 and

expected completion is mid 2025

HMA Power Generation enhances boiler fuel efficiency to improve profitability and decrease pollution at Ombilin power station in Indonesia. The unique Greenbank CoalFlo® damper and pulverised fuel metering system, installed as a complete fuel balancing solution, has provided this regional power station with the means to review, monitor and adjust consistency and balance of fuel into the burners.