STM

STM Spa was formed in 1976 and in that time, has grown from a small gearbox producer, into one of the world’s leading manufacturers of Industrial Gearboxes and Geared Motors. In the year 2000 STM Spa acquired the Heavy-Duty Gearbox manufacturer GSM Spa in order to provide customers with a ‘total solution’. STM Spa and GSM Spa come together to form STM Team and produce more than 30,000 gearboxes each month for customers all over the world STM Spa and GSM Spa production facilities are spread over 70,000sq/m, over 6 plants and employing over 300 people.

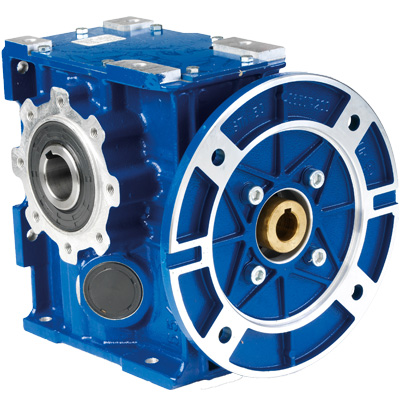

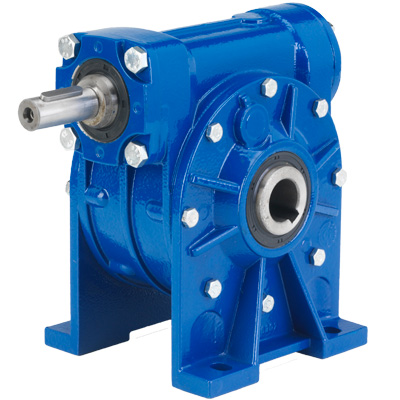

STM team manufactures the widest and broadest range of gearboxes and geared motors. STM team provides forefront technical solutions in every field of light and heavy mechanics according to specific user’s requirements and is expressed through one single policy: High technology for successful products.

Nowadays Italian factories are characterized by the de-location of their production sites. On the other hand, STM goes on investing in Italy with research, brand and innovation. STM range of products is completely made in Italy. Due to the company’s policy based on constant development. STM increases and improves continuously the manufacturing sites by installing more and more modern machine tools and equipment, thus enhancing continuously the output and also the product quality. The strategic part manufacturing is made internally with robotized machining centres of the latest generation, served without supervision. As a matter of fact, this strategy increased the employment and the volume of sales, so that STM could open the new production plant.

Completion and restructuring of company logistics with a fully automated warehouse that ensures accurate replenishment of materials, offers rapid service to meet the urgent needs of our markets.

Day after day STM undertakes to minimise both the use of natural resources and the environmental impact at the planning stage and during the entire manufacturing process. For us at STM the main objectives in the search for innovation are to develop the corporate activities responsibly and to support a sustainable economic growth. Since 2010 and thanks to the use of dedicated systems that collect and purify water and oil resulting from machining processes, STM is saving up to 40% of the resources needed during manufacturing, thus markedly reducing the company’s environmental impact.

STM initiated and completed the construction of a photovoltaic system for the production of electricity, in order to reduce the impact of the consumption of traditional resources for its energy needs and limiting the emission of polluting gases. Now generating in excess of 700 Kw.

History

1976

The year 1976 is not only a date for S.T.M. It represents the starting of a small company that is today an important reference point in the mechanical transmission field, thanks to the entrepreneurial capabilities, the expertise and firm commitment of the promoting partners (Girotti Tiziano, Vignoli Altero and Lucchini Giuseppe).

1982

S.T.M., confirming the attention to the safety and protection of machinery, designs the first torque limiter integrated in the worm gear is still used with great success in the most important applications.

1990

S.T.M. has turned over 90′ from a craftsman like expression into a big industrial company specialized in the design and manufacturing of speed reducers.

S.T.M. is nowadays well known in national and international markets in which it has reached a most respected position.

1998

In 1998 S.T.M. achieved ISO 9001 Certification, with the aim of granting a good quality system for the different market needs.

Today S.T.M., using modern design systems and high-tech production machineries (working centres, gear cutters, and sophisticated grinding centres), can offer a wide range of speed reducers, electric motors, mechanical and electronic variators.

2000

S.T.M., demonstrating the vitality and the intention to globalize its presence by strengthening the competitive factor in the market by completing the offer, acquired the company G.S.M. Spa by means of a high technological know-how. It produces high power gearboxes and geared motors.

The construction of a new building starts: 5.000 square meters to assembling and shipping.

2003

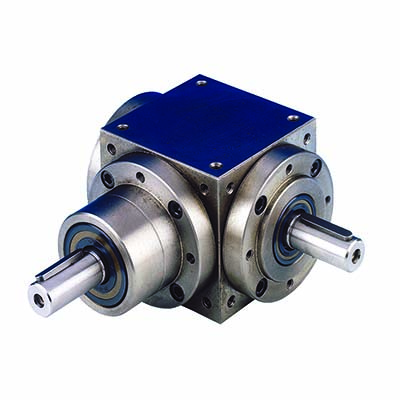

S.T.M. being always looking for new innovative solutions designs and sells, for the first time in the world, the orthogonal axes skew gearbox with at least two axes of reduction.

2008

S.T.M. builds a new 4.500 square meters warehouse for products storage, in order to improve the logistics.

2009

S.T.M. introduces EX series planetary gearbox after two years of planning and study, widening and strengthening its product portfolio.

2014

S.T.M. uses the most modern design and production systems, work centre, gear-cutting machines, sophisticated grinding lines and it can offer a wide range of gearmotors, drive systems and planetary gearboxes to satisfy the most demanding market.

The need of an always more and more efficient and effective structure concerning human resources and production spaces is the reason why S.T.M. covers an area of 70.000 sqm, including a 44.000 sqm indoor area (6 plants).

Today S.T.M. team offers one of the widest products range in the power transmission field, employs 306 people and reaches a sales turnover of more than 82 Million Euros all over the most important national and international markets.

2015

S.T.M., in order to improve the quality standards and customer service, begins the construction of the new logistics centre.