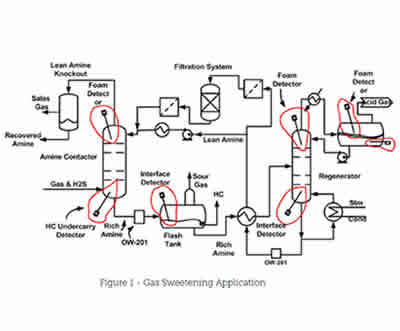

The Agar Foam Detector can detect the presence of foam far earlier than a ΔP cell, pressure gauge or other technologies. The probe can initiate or increase the anti-foam chemical injection rate causing the foam to dissipate.

The Agar Foam Detector can detect the presence of foam far earlier than a ΔP cell, pressure gauge or other technologies. The probe can initiate or increase the anti-foam chemical injection rate causing the foam to

dissipate. As a result, the anti-foam chemical feed rate is optimized, reducing the operator’s overall chemical costs.

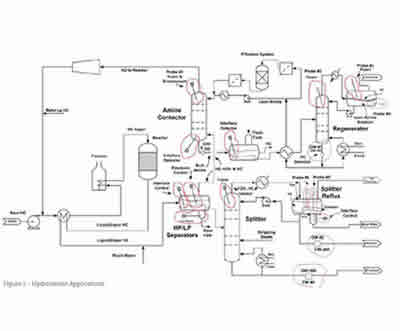

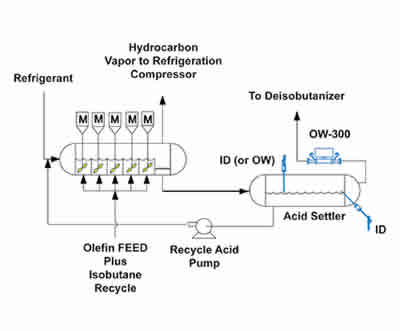

Alkylation is an important refining process in which light olefins (e.g. propylene, butylene) are converted into higher value gasoline blending components with improved octane and vapor pressure properties. Agar

technology can be applied in the alkylation process in two fundamental categories.

If a fire, smoke or gas leak is detected in an industrial facility, prescriptive actions must be taken by the fire and gas safety system, as well as the process control system, to mitigate and control the hazard. Using a certified, documented fire and gas safety system that can communicate appropriate messages to the process control system during an event is vital to the safety of a facility and its occupants.

AAR MRO Services supports airline operators with everything from maintenance inspections and equipment upgrades to airframe painting and heavy maintenance for all major aircraft in service. The largest MRO operator of its type in the Americas, AAR recently opened the company’s largest facility, located at the Chicago Rockford International Airport.

HMA Ceramic Lined Butterfly Valves are the product of a synergy that combines the industry experience and technical knowledge of both the Flow & Industrial and Wear Solutions divisions. The objective was to create a something with the functionality and footprint of a standard butterfly valve but with the superior life expectancy of ceramic lined pipework while ensuring the solution remained cost effective for our clients.

In 2012 a large refinery in New South Wales came to a realisation – it needed to convert to a fuel tank farm and subsequently reduce staffing levels. Such a significant change would inevitably lead to the challenge of upgrading its fire protection and detection systems, to allow the site to become more automated and responsive in emergency situations...

HMA Instrumentation recently offered the Holiday Inn Rotarua a free of charge trial of the Fireye NXM2G Intelligent Boiler Load Controller. The NXM2G measures the supply and return temperatures of a hot water boiler systems via digital sensors and monitors the “call for heat”...

A refining company based in New Zealand recently installed the Turbinator, via an engineering consultant. Below are their comments on the unit...

Port Augusta Power Station in South Australia is now enjoying a safe and secure onsite supply of hydrogen from HOGEN. This means that they would no longer need to rely on bottled gas by gas suppliers and take advantage of extreme high purity of 99.9999% hydrogen produced by causticfree electrolysis.

In a coal dryer system, flexible joints are used on inlets and outlets of the gas recirculating fans. These joints are primarily to isolate vibration to the structure and some minor thermal expansion.

FORT WASHINGTON, Pa. – 3 October 2012 Severn Trent De Nora announced today that the MARINER OMNIPURE® marine sewage treatment system M5508 model will be used on the FY17, a new luxury superyacht to be constructed by Fitzroy Yachts of New Zealand for delivery in 2014. The FY17 is a fast cruising sloop that measures 37.5m in overall length.

The existing fire and gas detection systems at the sites (see The Sites panel) needed to be updated. The STOS I&E engineer responsible for Fire and Gas systems across the company said “The project was initiated to enhance even further the safety of our people, assets and the environment through increased Fire & Gas detection.” STOS enlisted Transfield Worley to undertake a study of the potential systems and detection devices they could use.

Power plants and paper mills use service water loops and mill water loops respectively for the cooling of lubricating, hydraulic, turbine and transformer oil. These cooling systems feature large, recirculating volumes of water which are treated with biocides, dispersants, and corrosion inhibitors.

Worldwide growth in the use of natural gas has increased the need for transporting it – and the most economic method of transporting natural gas is in its liquefied form, which is 600 times denser than its gaseous form.

The several proprietary processes used to make LNG involve refrigerating the gas and then expanding it to turn the gas into a cryogenic liquid.

Start with high-risk processes, add combustible or toxic liquids and gases, and then place these hazards in far-flung locations and inhospitable environments. This is the real-world formula for industries’ most challenging fire and gas safety system applications.

Power Plants, Steel Mills and other heavy industrial plants and Municipal Water Treatment Plants often have an open water basin which they need to measure for oil concentration. The water can be in a sump or open

channel with in the plant or in an open body of water like a River, Lake or the Oceans.

Wastewater treatment plants (WWTPs) and collection facilities need to be protected against the dangers of combustible and toxic substances. This is the role of a fire and gas protection system as defined for WWTPs by NFPA® 820 and other standards organizations.