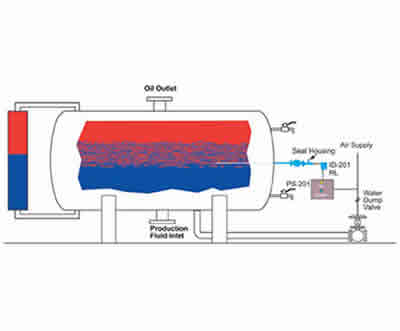

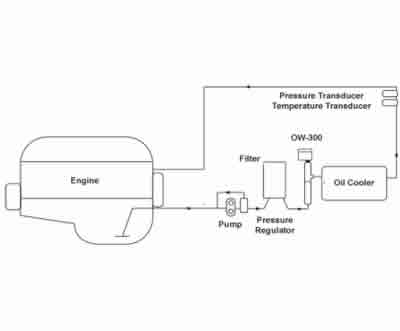

Industrial lubrication systems require close monitoring of the lubricating fluid to detect contaminants and prevent the resultant degradation of the fluid. Contaminants such as water and metallic fines are commonly monitored manually, requiring routine sampling and laboratory analysis.