Polyurethane Impact Panels

More Information

WEA-DS-0008-Polyurethane-Liners

Australia Tel: +61 (0)2 4389 6191

Indonesia Tel: +62 21 3040 4422

New Zealand Tel: +64 (0)7 850 2610

South Africa Tel: +27 (0)10 900 2055

Description

Polyurethane sheets & liners are made of high quality cast polyurethanes, which provides excellent wear and impact resistance in raw material handling applications. Our liners are often used as a replacement for steel liners.

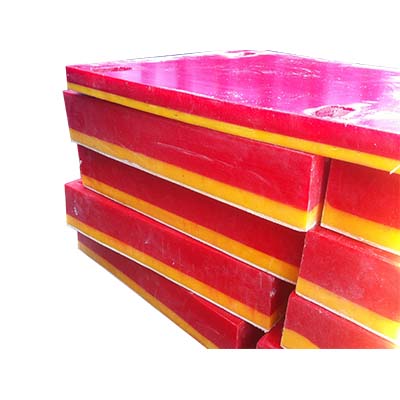

Uretech polyurethane sheets and liners from HMA Wear Solutions are made from high-quality cast polyurethanes for excellent wear and impact resistance in raw materials-handling applications. These liners are often used as a replacement for steel liners. The sheets and liners are fitted with a unique fibre-reinforced backing plate for added stiffness. Liner stiffness is essential to prevent bulging. The fibre-reinforced backing plate is easier to cut than traditional steel backing plates, rendering it more cost-effective, as the liners can be cut to size in the factory, or on-site.

Sheets over 16 mm thick have wear indicators (one-third yellow) built into the liners, enabling end users to gauge the thickness of the liners from the top, thus improving preventative maintenance. The Uretech polyurethane sheets and liners from HMA Wear Solutions are safe and easy to transport, handle, and install. The fact that polyurethane absorbs sound, rather than reverberating, makes for a substantial reduction in noise levels. Polyurethane also has excellent ‘memory’ or ‘rebound’ properties, enabling it to recover under pressure.

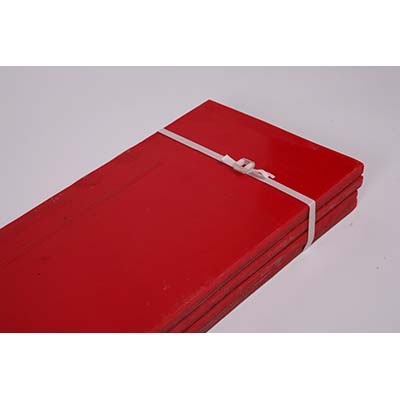

Uretech manufactures standard 2400 mm x 1200 mm sheets. These sheets can be cut into customised shapes and sizes to fit any application. Uretech can manufacture liners in any thickness, with 12 mm to 40 mm being the most popular. Sheet-thickness selection is usually determined by the life expectancy in a specific application. Installation is by the following adhesion methods: Bolts and nuts, studs and nuts, nail gun, or Uretech liner glue.