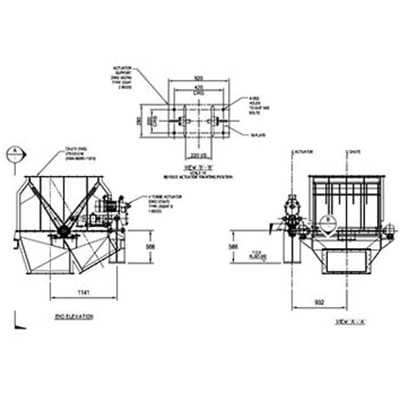

Diverter Gates

More Information

Australia Tel: +61 (0)2 4389 6191

Indonesia Tel: +62 21 3040 4422

New Zealand Tel: +64 (0)7 850 2610

South Africa Tel: +27 (0)10 900 2055

Description

Diverter Gates from HMA Materials Handling are used extensively in the bulk materials processing industry to direct the flow of material to various processing circuits, regulate the flow to various circuits and to isolate circuits for maintenance. They can be as basic as a single to double diverter with a manual lever to change blade position from one side to the other, or they can be fully-automated devices capable of proportioning flow from one or more sources to a large number of destinations.

Diverter gates from HMA Materials Handling can be of two designs, depending on the characteristics of the material being handled. A simple flat blade diverter is applicable for most materials and is relatively inexpensive and easy to install and maintain. For some material, the non-jamming characteristics and sealing capabilities of the rolling blade diverter make it more suitable.

Applications:

- To direct material from a receiving source, such as a belt, pneumatic or other type of conveyor, to two or more process lines or storage bunkers individual or proportionally, requires the use of some type of diverter gate

- If a process consists of multiple parallel process circuits, diverter gates are used to isolate individual circuits for maintenance purposes

- To maximise the capacity of process plants with multiple parallel process circuits, diverter gates are used to balance the feed to each circuit

Diverter gates can be fabricated from or equipped with a wide range of construction materials, depending on the characteristics of the bulk material being handled. Some examples of construction materials for different applications are:

- Carbon steel with abrasion-resistant liners can be used for most applications

- Polished stainless steel liners can be used to reduce the friction between the bulk material and the gate surface, thereby reducing flow problems

- Stainless steel can be used in all areas in contact with acidic material to prevent corrosion. In some instances, it may be necessary to fabricate the entire gate from stainless seal

- Plastic and rubber seals and liners can be used for a wide range of design features. For example, rolling blade gates can use rubber seals, and both types can be equipped with internal or external rubber liners for noise abatement

Especially for totally sealed gates, it is important to have a method of determining the position of the gate blade. For gates used to adjust the flow of material, it is necessary to monitor the position of the blade at all times. For some gates it is necessary to determine when they are closed, for others whey they are open and for others when they are both open and closed. Some of the devices available to determine the gate blade position are:

- A limit switch can be used to detect whether the gate is closed, open or any preset intermediate position

- A proximity switch can be used to detect the closed, open or any pre-set intermediate position

- A sensor can be used to continually detect the gate blade position

- For visual indication, the actuator is usually visible

- Integral position indication is available from actuator manufacturers to indicate the gate blade position