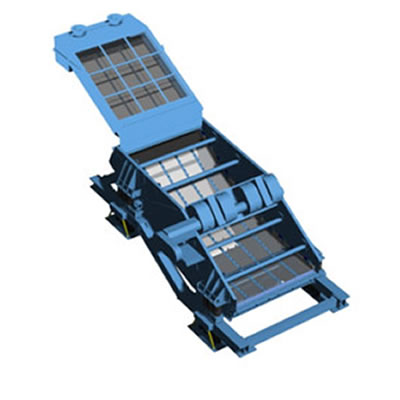

Conn-Weld® Sieve Bends

More Information

Australia Tel: +61 (0)2 4389 6191

Indonesia Tel: +62 21 3040 4422

New Zealand Tel: +64 (0)7 850 2610

South Africa Tel: +27 (0)10 900 2055

Description

Conn-Weld Sieve Bends from HMA Wear Solutions are the end result of more than 35 years’ field experience working with plant circuits and systems. Special features include the quick reversal turnaround system and adjustable feed gate. Every Conn-Weld Sieve Bend from HMA Wear Solutions is manufactured in accordance with the highest quality and durability specifications, with rugged components for maximum uptime and simplified maintenance. Advantages include a smaller footprint needed for installation, minimum structural support, no moving parts or vibration, no horsepower required, and a turnaround designed for quick screen reversal.

Conn-Weld from HMA Wear Solutions manufactures the widest range of Profile Sieve Screens in the industry today, with particle separation ranging from 40 µ up. The profile screen surface has knife-sharp edges for removal of layers of liquid and undersize material as the liquid passes the opening, thus preventing blinding of the slot opening. The undersize material is classified at about one half of the screen opening.

Conn-Weld Flat and Flume Style Sieves from HMA Wear Solutions can be combined with vibrating screens for efficient feed distribution, increasing the screen wear life and reducing the operating costs compared to traditional curved sieves. The capacity is also higher, while screen panel sizes have been standardised. Custom-engineering means that any customer-specific requirements can be accommodated effectively.