Cascade Coil ® Safety Barriers

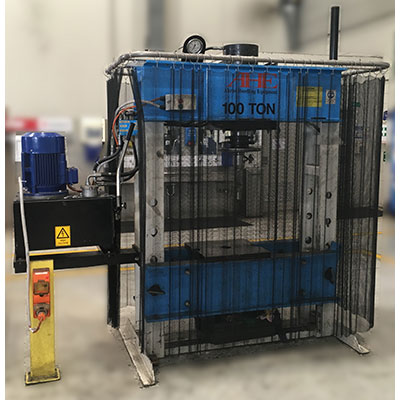

Wire mesh curtain provides a clear view of the equipment while keeping the operator safe. GuardianCoil® products are available in a wide variety of wire types, gauges and weave sizes to suite all applications.

Prices are per side of press and include a fullness allowance of 1.5 times the selected width. Includes safety hooks.

More Information

MAT-DS-0001 Retractable Guarding

MAT-DS-0027 Cascade Safety Security

MAT-DS-0029 Cascade Fabricoil Blast Protection

MAT-DS-0032 GuardianCoil Blast Mitigation.pdf

MAT-ML-0002 Cascade Coil Mesh Hook Installion

Australia Tel: +61 (0)2 4389 6191

Indonesia Tel: +62 21 3040 4422

New Zealand Tel: +64 (0)7 850 2610

South Africa Tel: +27 (0)10 900 2055

Description

Installing Cascade Coil Guardian Coil® safety screens around machines and equipment can be an effective step towards improving safety at work, reducing injuries and fatalities in the workplace. Cascade Coil Guardian Coil® is custom manufactured from interlocking spirals of steel wire. The unique metal mesh forms machine guards, catching flying or dropped objects. This improves machine safety blocking debris from ever reaching the operator.

Flying and falling objects are principal occupational health and safety hazards in many manufacturing environments. Each year workers are struck by ejected debris such as metal chips, nails, broken cutters, blades, tools and dislodged grinding wheels causing unnecessary injuries and potential lost time. Job safety analysis and personal protective equipment assist in minimising injuries and fatalities caused by airborne particles.

Cascade Coil Guardian Coil® is available in steel and stainless steel, a wide range of wire types, gauges and weave sizes with various coatings and finishes to suit all applications. Through the proper selection of weave and wire gauge, a solution can be tailored to your specific safety guarding needs. Our manufacturing technique allows the finished product to be flexible in one direction, giving you more design options than traditional fencing or solid metal barriers.

Applications:

Machine Guards

Cascade Coil Guardian Coil® safety barriers are safety equipment for improving occupational health and safety around all types of machinery. Working as a protective screen Cascade Coil Guardian Coil® is suitable with a milling machine, drill press, routers, spar mills, lathes, grinders, forges, testing equipment, etc. The safety mesh improves drill press safety and is used as a machine guard to protect personnel and property from high-velocity flying debris or shrapnel.

Cascade Coil Guardian Coil® machine guards allow easy access to machines while providing a lower-cost method of meeting OSHA guard standards. As the metal mesh safety barriers are typically black, safety yellow or stainless steel, the machine operator’s eyes can easily focus on the point of operation. The safety curtains are lightweight, easy to install, are maintenance free and allow natural light visibility.

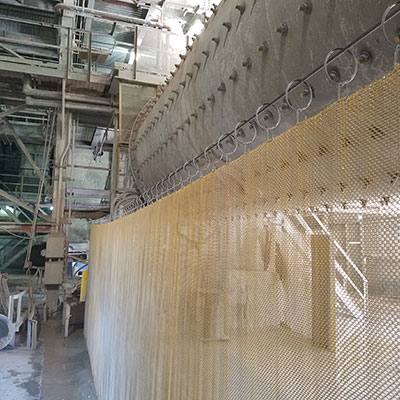

Conveyor Systems

Cascade Coil Guardian Coil® safety curtain aids in pinch point safety and overall conveyor safety. The metal mesh curtain provides a clear view of the equipment while keeping the operator safe.

Cascade Coil Guardian Coil® Key Features:

Fireproof and Virtually Maintenance Free

- 100% Fireproof, doesn’t absorb oil, grease or other flammable liquids, can be easily cleaned.

- Damaged sections easily replaced by splicing in the new panels on site.

Durability

- Superior break-through strength and corrosion resistance.

- Lightweight and long-lasting.

Flexibility

- Expands and contracts in one direction allowing easy access to work areas.

- Dissipates a projectile’s kinetic energy by enveloping around the object.

- Minimal structural support requirements due to lightweight construction.

- Wide assortment of stainless hooks, split rings, track systems, and other hardware is available.

Enhances Supervision and Productivity

- The flow-through design allows ventilation and light into the work area.

- Visual observation of both the machinery and operator allows enhanced supervision, productivity, and safety.

Custom

- Manufactured to your size and application specifications.

- Wide variety of weave sizes and materials available to suit application requirements.

- Unlimited variety of colours available.

Installation

- Typically secured at the top and hangs free at both sides as well as the bottom.