B&W Diamond Power Carryover Monitoring System

Australia Tel: +61 (0)3 5136 8400

Indonesia Tel: +62 21 3040 4422

New Zealand Tel: +64 (0)7 850 2610

Description

Carryover Monitoring System

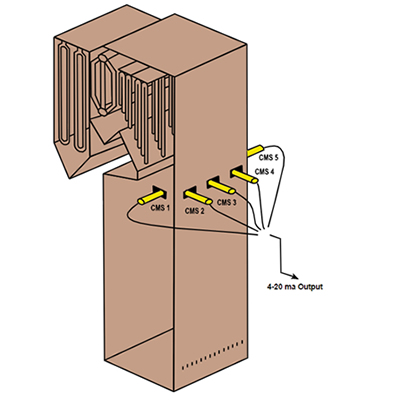

The CMS monitors on-line, luminous particle activity in the boiler. By employing multiple sensors to detect particle activity at selected locations in the upper boiler, the CMS allows operators to monitor particle carryover in several locations at the same time, a feature unique to this system.

Fluctuations in black liquor firing or combustion air can resThe CMS monitors on-line, luminous particle activity in the boiler. By employing multiple sensors to detect particle activity at selected locations in the upper boiler, the CMS allows operators to monitor particle carryover in several locations at the same time, a feature unique to this system.

Fluctuations in black liquor firing or combustion air can result in unburned char particles or carryover being entrained in the flue gas and deposited on tubes in the convection pass of the boiler. Entrainment of char and smelt is one of the major causes of convection pass plugging.

Application

Pulp & Paper Recovery: ecovery: ecovery: The Carryover Monitoring SystemÈ (CMS) can be used by operators to identify instances, operating conditions, and regional variations of carryover of unburned char to the convection section of the boiler. Reducing the carryover of unburned char particles can reduce fouling and plugging, and increase boiler run times.

Utility: Utility: CMS Utility: can be used on stoker fired, bubbling bed and fluidized bed boilers to monitor carryover of unburned fuel particles to the convection section of the boiler. Reducing the carryover of unburned fuel particles can reduce fouling and increase boiler run times.

Features & Benefits

- Optical sensor to measure luminous particles (carryover) at the furnace exit.

- Provides a 4-20 mA and a local display output signal. Can be input to plant Distributive Control System or The Fireside Advisor System.

- Sensors can be installed in multiple locations to detect variations in fouling over the boiler width.

- Identifies conditions likely to result in plugging problems, and likely locations, before they become critical.

- Improves efficiency by indicating abnormal boiler conditions and combustion regions.

Specifications

- Power Requirement equirement: equirement

- 120/240 VAC, 50/60 hz, 2 amp

- Cooling Requirement equirement: equirement

- 15-20 psig, 15 scfm compressed air at <130ºF

- Operating Requirement equirement: equirement

- 0-185ºF, 0-90% relative humidity

- Measurement Field-of-View: 8 degree cone View

- CMS Data Readout Update Period:

- 1 second to 15 minutes (adjustable): 5 seconds typical

- Dynamic Response: esponse