HMA Materials Handling have been designing and building train loading systems for various materials in the bulk material handling industry for over 20 years. Our Systems are designed specifically to suit of customers individual requirements with the aim of maximising the amount of material loaded into each wagon to fully utilise the available train capacity.

HMA train loading systems can be operated both Manually or in a fully Automatic mode eliminating the need for constant operator intervention and use the latest technology around train monitoring and functional safety to ensure the safest most robust systems available on the market today.

Train loading systems and typically classified in one of the below two categories:

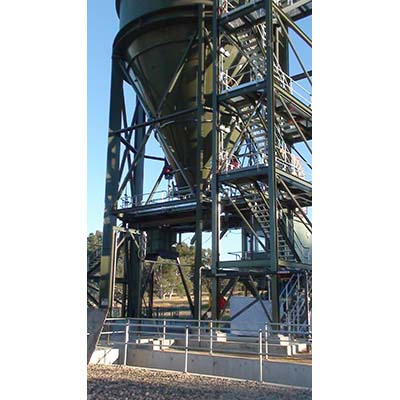

Precision Batch Train Loading (Gravimetric Loading): Batch loading is done from a dual bin system consisting of a Surge bin and Weigh bin with the material being Pre- weighed in the weigh bin prior to being discharged into the wagon which allows for wagons to be loaded accurately to a Target weigh. HMA Materials Handling holds the patent for the Precision Loading System (PLS) in the Australasian region. The PLS uses a multi-batch approach to the loading of bulk materials in both trains and trucks which allow for significant cost savings over traditional single batch loading systems without any compromise on loading accuracy, safety or performance.

Volumetric Train Loading (Flood Loading): Volumetric loading is done from a single bin without and pre weighing of material and allows for wagons to be filled based on volume only.

Materials such as coal, iron ore, gravel and sand can all be loaded in bulk using our variety of designs and operating systems. Loading systems are also available to suit applications involving trucks (including oversized and multiple wagons) as well as trains.