BS&B

The BS&B name is well known for the innovative design of Rupture Disks, Buckling Pin Valves, Flame Arresters and Dust Explosion Protection Equipment integral to the industry’s safe and efficient operations.

The invention of the world’s first Rupture Disk (bursting disc) in 1931 provided a safe and reliable pressure relief mechanism to not only protect such equipment, but also a means to provide for personal protection against dangerous over pressurisations and damaging vacuum conditions. In 1966 the invention of the Reverse Buckling Rupture Disk offered superior resistance to operating conditions, greater accuracy and reliability. Then with the development of the Scored Reverse Buckling Disk in 1972, the combination of rupture disk devices with pressure relief valves was born. Changing from a perfect seal to a full open flow area in milliseconds, the Rupture Disk compliments the reclosing characteristics of relief valves, enhancing pressure relief system reliability, particularly for owners and operators of hazardous and toxic materials processing and storage facilities. With the growth in processing and handling of dry plastic materials in pellet and powder form, together with the large scale processing of dry agricultural products, BS&B Rupture Disk technology was further developed to achieve the large relief areas and low set pressures required for explosion venting of combustible dust hazards.

1993 saw the development of explosion suppression technology and lead to the Industrial Dust Explosion Protection Equipment range. BS&B protects the dry materials industries, from chemicals to foods, and from pharmaceuticals to power generation.

The Buckling Pin Relief Valve (BPRV) was invented in 1995 and further developed to achieve ASME and CE certification in 2005. Designed to protect large piping systems from overpressure, the BPRV is the safety solution for the API compliant flare systems used by the oil and gas industries.

BS&B Safety Systems are all around you, in transportation systems, power generation, transmission and distribution systems, medical equipment, chemical and pharmaceutical process plants, as well as the food and beverage industries.

BS&B Safety Systems – Rupture Disk

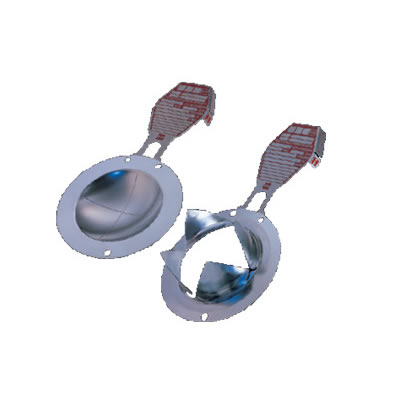

Rupture Disk Devices

BS&B provides application choices with the industry leading range of reverse buckling, forward acting, and graphite rupture disk devices. Within each of these three technology groups are further choices to attend to each of the users specific application needs. Additional speciality designs provide protection for sanitary/aseptic systems and transportation equipment.

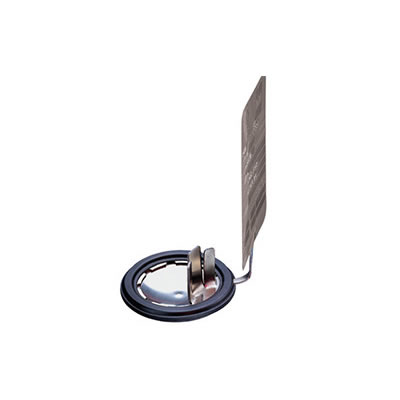

BS&B Safety Systems – Buckling pins

Buckling Pin Valves

The BS&B Buckling Pin Valve technology is focused on providing the highest flow capacity available from both in line and angle valve devices. BS&B Buckling Pin Valves are fast acting / quick opening pressure relief devices that offer rapid and easy field reset, dramatically reducing plant downtime after activation. The 60 inch (1,500mm) BPRV (page 125) is the world’s largest ASME certified pressure relief device. Custom designed spring loaded pressure relief valves compliment the BS&B speciality valve range.

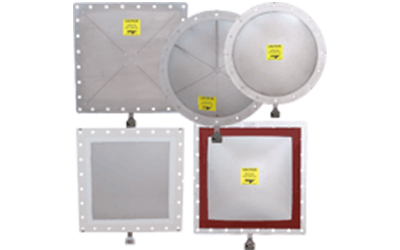

BS&B Safety Systems – Industrial explosion protection

Industrial Explosion Protection

BS&B have the most practical safety solutions for combustible dust processes. Designing client application solutions, BS&B enables users to achieve compliance with NFPA, OSHA and ATEX standards while maintaining process throughput and economy. With the widest range of explosion protection, flameless venting, isolation and suppression, BS&B provides the most complete options to the end user.

BS&Bmanufactures a range of protection technology including explosion venting, explosion suppression, chemical and mechanical systems for the isolation of interconnected process equipment, spark detection, and extinguishing equipment to manage a source of both dust explosion ignition and fire.

BS&B Safety Systems – flame arrestors

Flame Arresters

BS&B FlameSaf are dedicated to protecting industrial plants and personnel from the dangers of explosion and fire propagation typically in hydrocarbon service. FlameSafTM arresters protect from both deflagration and detonation conditions with product certified to EN / ISO 16852: 2010 and are complemented by a range of pressure and vacuum breather vents.

BS&B Safety Systems – Custom Products

Custom Engineered Products

BS&B services original equipment manufacturers (OEM) as well as the defence and aerospace industries with both standard and custom overpressure relief solutions configured to perform accurately and efficiently. An unrivalled range of rupture disk technology satisfies applications from low pressure to over 50,000 psig (3,500barg). The technology trinity of FRB, QRB, and MRB reverse buckling disks provides superior performance where compact dimensions are required. From a single custom designed component to high volume applications, our design experience and manufacturing support capabilities are ready to meet your challenge. Over 200 million installations and growing.